Roland Perry

2022-07-05 10:27:44 UTC

Mainly about the eastern side (surface building 23 Long Lane, which is

consistent with the building next door being signed 18-19; a mystery why

#66 also turns up on Google). Looking west along Long Lane:

Loading Image...

The name over the doors(s) is Farringdon, and there are sliding doors

facing both Long Lane and the side-roads, although so far they only

appear to use the side-road opening. Note the duplicate "No Entry" and

Farringdon" signage facing Long Lane.

Down at platform level there are signs indicating which end of the

platform to use if wanting either Farringdon Tube/National Rail, or

Barbican (the complex, not the station).

htp://www.perry.co.uk/images/Farringdon-PlatformSign.jpg

Starting afresh from EL platform level looking up (southeast), there are

two similar-length banks of escalators, with an 'Interchange' (aka

mezzanine) level. Each bank has an inclined lift on the left parallel

with the escalators.

The famous "secret lift" [G] is in a lobby off the left of the

Interchange Level, and here's the layout diagram inside the upper

inclined lift:

Loading Image...

Aside: it's not obvious why the upper bank has an inclined lift, rather

than a vertical one with horizontal passages top and/or bottom. Like at

Kings Cross Northern Ticket Hall. Unless they wanted symmetry, or

there's something under the surface in the way (which is one suggestion

for needing the lower inclined lift).

The secret lift-G is a shorter trip that I was expecting, but that's

explained by the upper entrance being on a sub-surface platform. And

which of course pinpoints where the Interchange level is (directly under

the western end of the Barbican station platforms). Being as far as it's

possible to get from the Barbican ticket office, the lift isn't

something most people would notice.

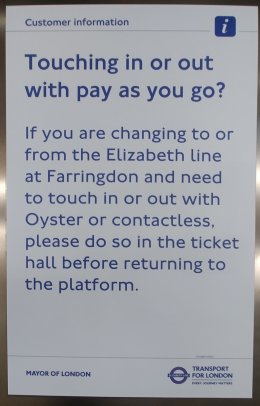

Meanwhile, back at the western end of the station, the "passage" with

'missing' validators is very short, with the Northbound Thameslink

trains right in front of you, and is more of an extension to the final

intermediate (almost at the top) concourse. There's a sign on the wall:

Loading Image...

For symmetry with other parts of the station I can't help feeling a

gateline there would be more intuitive for the passengers. Even if it

means a redundant touch for many passengers. My recollection is that one

of the earlier double-ended stations (Southwark, Jubilee Line) has one

if you want to exit onto Blackfriars Road, via the tube station, having

arrived at Waterloo East National Rail, .

consistent with the building next door being signed 18-19; a mystery why

#66 also turns up on Google). Looking west along Long Lane:

Loading Image...

The name over the doors(s) is Farringdon, and there are sliding doors

facing both Long Lane and the side-roads, although so far they only

appear to use the side-road opening. Note the duplicate "No Entry" and

Farringdon" signage facing Long Lane.

Down at platform level there are signs indicating which end of the

platform to use if wanting either Farringdon Tube/National Rail, or

Barbican (the complex, not the station).

htp://www.perry.co.uk/images/Farringdon-PlatformSign.jpg

Starting afresh from EL platform level looking up (southeast), there are

two similar-length banks of escalators, with an 'Interchange' (aka

mezzanine) level. Each bank has an inclined lift on the left parallel

with the escalators.

The famous "secret lift" [G] is in a lobby off the left of the

Interchange Level, and here's the layout diagram inside the upper

inclined lift:

Loading Image...

Aside: it's not obvious why the upper bank has an inclined lift, rather

than a vertical one with horizontal passages top and/or bottom. Like at

Kings Cross Northern Ticket Hall. Unless they wanted symmetry, or

there's something under the surface in the way (which is one suggestion

for needing the lower inclined lift).

The secret lift-G is a shorter trip that I was expecting, but that's

explained by the upper entrance being on a sub-surface platform. And

which of course pinpoints where the Interchange level is (directly under

the western end of the Barbican station platforms). Being as far as it's

possible to get from the Barbican ticket office, the lift isn't

something most people would notice.

Meanwhile, back at the western end of the station, the "passage" with

'missing' validators is very short, with the Northbound Thameslink

trains right in front of you, and is more of an extension to the final

intermediate (almost at the top) concourse. There's a sign on the wall:

Loading Image...

For symmetry with other parts of the station I can't help feeling a

gateline there would be more intuitive for the passengers. Even if it

means a redundant touch for many passengers. My recollection is that one

of the earlier double-ended stations (Southwark, Jubilee Line) has one

if you want to exit onto Blackfriars Road, via the tube station, having

arrived at Waterloo East National Rail, .

--

Roland Perry

Roland Perry